- Email support@dumps4free.com

Topic 3: Fabrikam, inc.

Case study

This is a case study. Case studies are not timed separately. You can use as much

exam time as you would like to complete each case. However, there may be additional

case studies and sections on this exam. You must manage your time to ensure that you

are able to complete all questions included on this exam in the time provided.

To answer the questions included in a case study, you will need to reference information

that is provided in the case study. Case studies might contain exhibits and other resources

that provide more information about the scenario that is described in the case study. Each

question is independent of the other questions in this case study.

At the end of this case study, a review screen will appear. This screen allows you to review

your answers and to make changes before you move to the next section of the exam. After

you begin a new section, you cannot return to this section.

To start the case study

To display the first question in this case study, click the Next button. Use the buttons in the

left pane to explore the content of the case study before you answer the questions. Clicking

these buttons displays information such as business requirements, existing environment,

and problem statements. If the case study has an All Information tab, note that the

information displayed is identical to the information displayed on the subsequent tabs.

When you are ready to answer a question, click the Question button to return to the

question.

Background

Fabrikam, Inc. manufactures industrial metal cutting machines. The company installs and

services the machines for customers.

Fabrikam has manufacturing plants in Canada, France, and China. The company also has

regional service organizations that are responsible for installation and maintenance of the

machines.

Current environment

Overview

Operations for the company are managed very informally. Only a small number of long term employees are aware of all manufacturing processes. The company has been

experiencing quality issues associated with its manufacturing operations and installations.

The company wants to implement a way to capture quality inspection results for each

machine produced. Current inspection checklists are stored in the Files section of a Teams

channel for inspectors. Inspectors commonly print the incorrect inspection checklist.

The company has specific inspection stations for certain inspection steps. Each station has

the gauges and equipment required for related inspection steps. There is often a backlog at

specific inspection stations. This results in delays in shipping machines to customers.

Accounting system

The current system does not handle shop floor or manufacturing planning

functionality.

Machines are assigned serial numbers and placed in stock until they are shipped

to customers.

Employee information is maintained only within the accounting system. Access to

the information is strictly controlled due to privacy regulations and company

policies.

Other systems

The company has an enterprise Microsoft 365 subscription. The company uses

Microsoft 365 only for sending and receiving email. The company uses photos of

employees to generate employee badges. Photos are uploaded into Microsoft 365

user profiles.

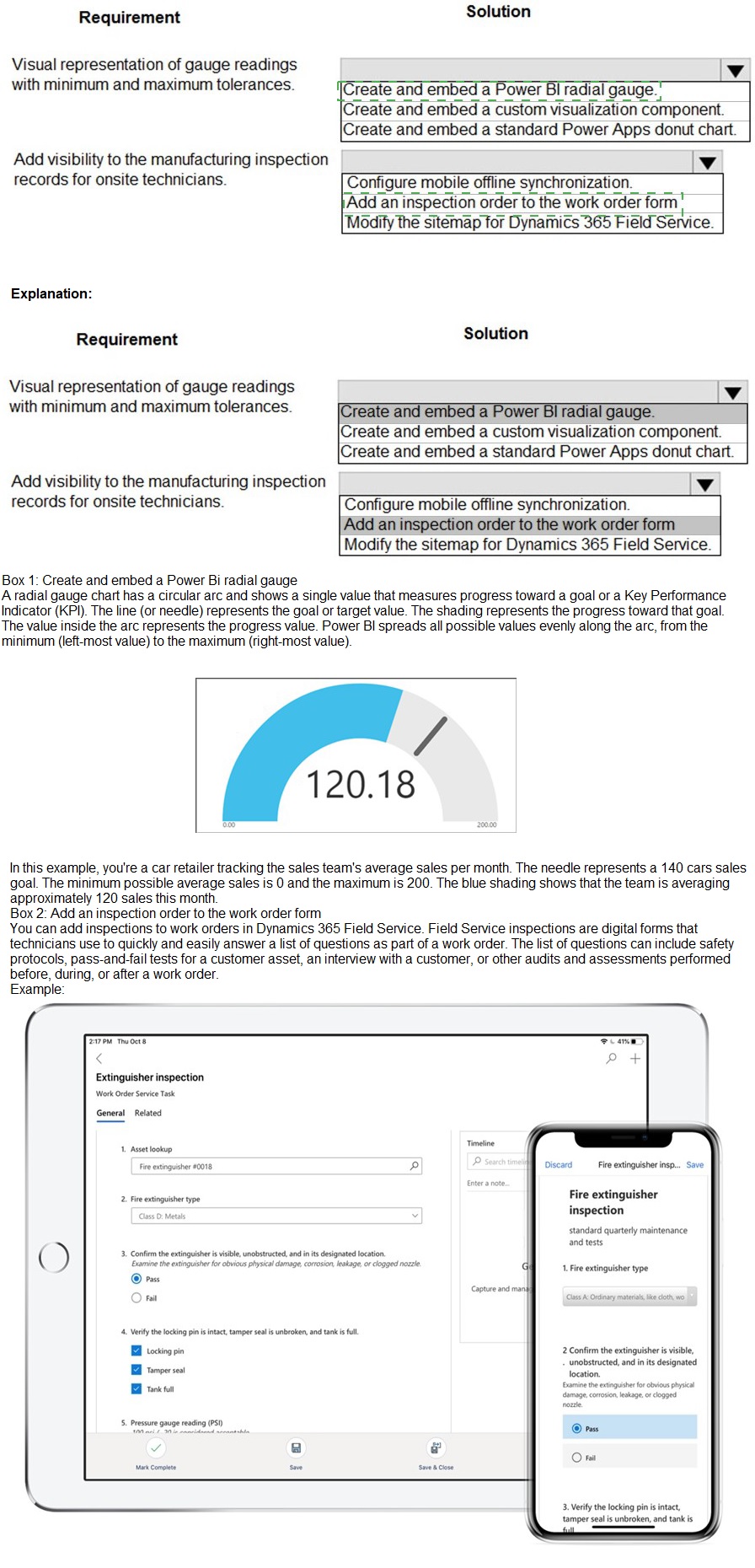

The company recently started using Dynamics 365 Field Service to manage and

maintain the machines that it installs for its customers. The app has not been

customized.

The company has added roles, skills, and certification proficiencies to Dynamics

365 Field Service resources to support both customer onsite inspections and final

manufacturing inspections.

Requirements

Quality inspection app

Fabrikam is evaluating Microsoft Power Platform to determine whether it can meet the

company’s requirements for a manufacturing defect and quality inspection solution. Each

machine produced must be subjected to a quality inspection at various points during

production. Each machine must undergo a more extensive quality inspection before the

machine can be shipped to the customer.

Inspection orders

Inspection orders must:

Inspectors must fill in findings comments and upload at least one photo for any

inspection step that is marked as failed.

Inspection standardization Standardized checklists must be stored in the solution for use by inspectors. A copy must

be created when a new inspection is initiated. The solution must:

Prevent an inspector from proceeding to the next step of the checklist until

required information for a step is entered.

Support the addition of steps to inspections to support custom features added to a

machine for a customer.

Support the direct input of measurements from testing gauges to avoid incorrect

readings being entered by inspectors.

Provide a visual representation of the testing measurement limits for each step.

Include an indication of how the measured value compares to measurement limits

and whether the measurement is within tolerance. Users must be able to configure

the visualizations to display the minimum value and maximum value, and whether

the reading is within the tolerance of a single targeted value. It must also be able

to be used for maintenance inspections once the machine has been installed.

Support the ability to store photo references within each inspection step to

document defects found during inspections.

Security

Users must be active employees of Fabrikam.

When a user signs into the inspection solution, the solution must display a picture

of the employee who has signed in.

Supervisors must be able to modify standard checklists. Other employees must be

prevented from modifying checklists.

You must prevent users from changing inspection order data once an inspection is

marked as final.

Analytics and reporting

The solution must:

Provide metrics including existing and upcoming demand by inspection station,

average time spent per user at a station, and average time a machine spends at

each inspection point.

Provide metrics per inspector including number of inspections performed by

month, and number of inspections per rating type (pass, fail).

Provide a printed quality certificate to be included with each machine.

Issues

During initial testing of the solution, testers report that they cannot see the photos taken

during a previously failed inspection.

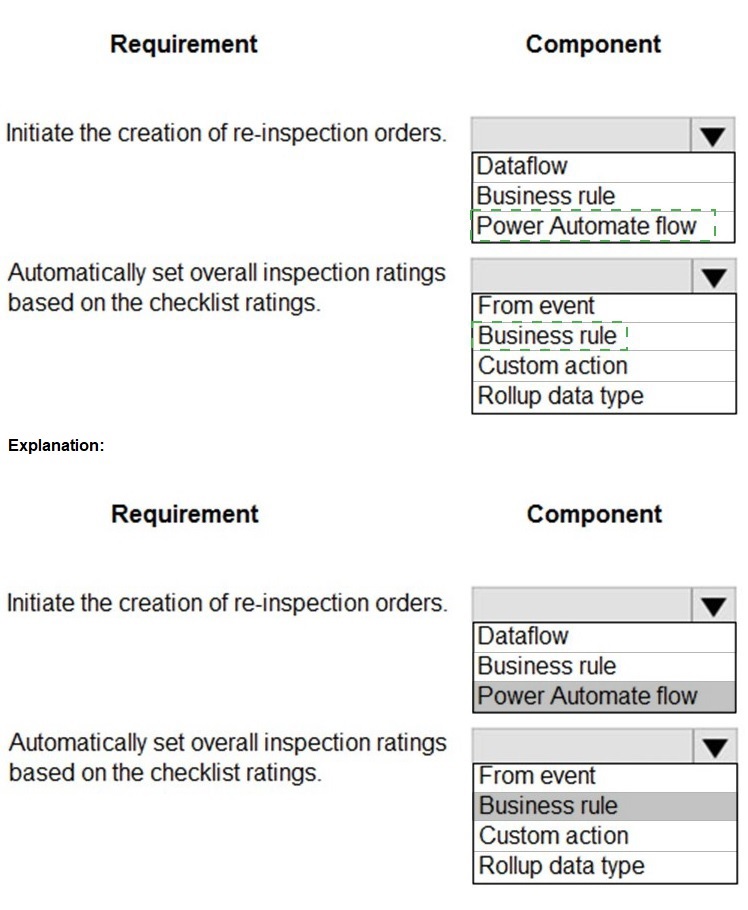

You need to recommend components to meet the re-inspection requirements.

Which components should you recommend? To answer, select the appropriate options in

the answer area.

NOTE: Each correct selection is worth one point.

Graphical user interface, text, application

Description automatically generated

Box 1: Power Automate flow

Scenario: Inspection orders must be automatically marked for re-inspection should a

machine fail inspection. The new inspection order must be created by using the originating

inspection order as a template.

Box 2: Business rule

By combining conditions and actions, you can do any of the following with

business rules:

Set column values

Clear column values

Set column requirement levels

Show or hide columns

Enable or disable columns

Validate data and show error messages

Create business recommendations based on business intelligence.

You need to recommend a solution to collect the information required to meet reporting

requirements.

What should you recommend?

A.

Business process flow

B.

Business rule

C.

Business event

D.

Business process modeler

Business rule

Business rule can create business recommendations based on business intelligence.

Scenario: Analytics and reporting

The solution must:

Provide metrics including existing and upcoming demand by inspection station,

average time spent per user at a station, and average time a machine spends at

each inspection point.

Provide metrics per inspector including number of inspections performed by

month, and number of inspections per rating type (pass, fail).

Provide a printed quality certificate to be included with each machine.

Reference:

https://docs.microsoft.com/en-us/learn/modules/define-create-business-rules/

You need to recommend a solution to meet user interface requirements.

What should you recommend? To answer, select the appropriate options in the answer

area.

NOTE: Each correct selection is worth one point.

You need to manage user access to the app.

Which two connection types should you recommend? Each correct answer presents part of

the solution.

NOTE: Each correct selection is worth one point.

A.

Virtual table with a customer connector

B.

Office 365 Outlook connector

C.

Microsoft Dataverse connector

D.

Office 365 Users connector

Microsoft Dataverse connector

Office 365 Users connector

Office 365 Users lets you access user profiles in your organization using your Office 365 account. You can use the Use the connection in your Power Platform app.

Dataverse is part of the Microsoft 365 collaboration and productivity tools. Using federation,

applications can connect to Dataverse using the same system user identities and

credentials available in an Azure Active Directory based network.

Scenario:

Users must be active employees of Fabrikam.

Quality inspection app: Fabrikam is evaluating Microsoft Power Platform to

determine whether it can meet the company’s requirements for a manufacturing

defect and quality inspection solution. Each machine produced must be subjected

to a quality inspection at various points during production. Each machine must

undergo a more extensive quality inspection before the machine can be shipped to

the customer.

Reference:

https://docs.microsoft.com/en-us/powerapps/maker/canvas-apps/connections/connectionoffice365-

users

You are evaluating a solution design for a model-driven app that will have a large number

of complex forms.

Many of the forms take up to 10 seconds to load.

You need to recommend solution to speed up loading times for the forms.

Which two solutions should you recommend? Each correct answer presents a complete

solution.

NOTE: Each correct selection is worth one point.

A.

Consolidate and reduce scripts.

B.

Use synchronous JavaScript requests

C.

Move scripts into the OnLoad event.

D.

Remove unnecessary fields

Consolidate and reduce scripts.

Remove unnecessary fields

Controls that require extra data beyond the primary record produce the most strain on form

responsiveness and loading speed. These controls fetch data over the network and often

involve a waiting period (seen as progress indicators) because it can take time to transmit

the data.

Keep only the most frequently used of these controls on the default tab.

Reference:

https://docs.microsoft.com/en-us/powerapps/maker/model-driven-apps/design-performantforms

| Page 7 out of 21 Pages |

| Previous |